JE60FMM

motor with mechanical setting by screws and manual operating system, for heavy shutters

What does the JE60FMM motor offer to roller shutters?

- End limits (upper and lower points) are made in the traditional way by the standard two screws located on the motor head

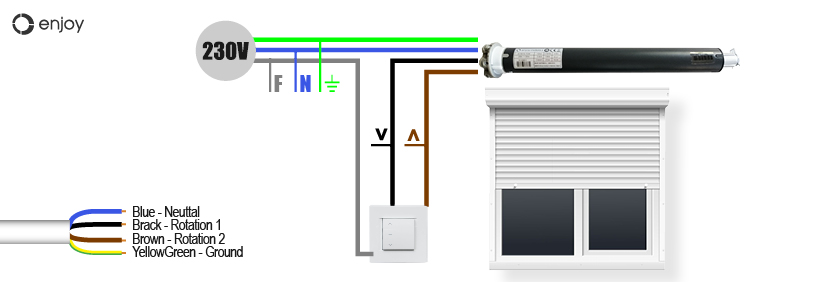

- Motor with 4-wire cable: Neutral (blue) and two wires corresponding to the direction of rotation (black and brown), in addition to the ground. To connect to a fixed switch or other external systems such as receivers, centralization modules or home automation devices

- Possibility to operate the motor, even in the absence of electricity, through a hand crank, thus providing the security that, if necessary, we can raise or lower the roller shutters

Main features:

Main features:

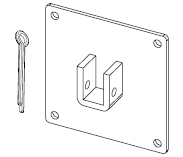

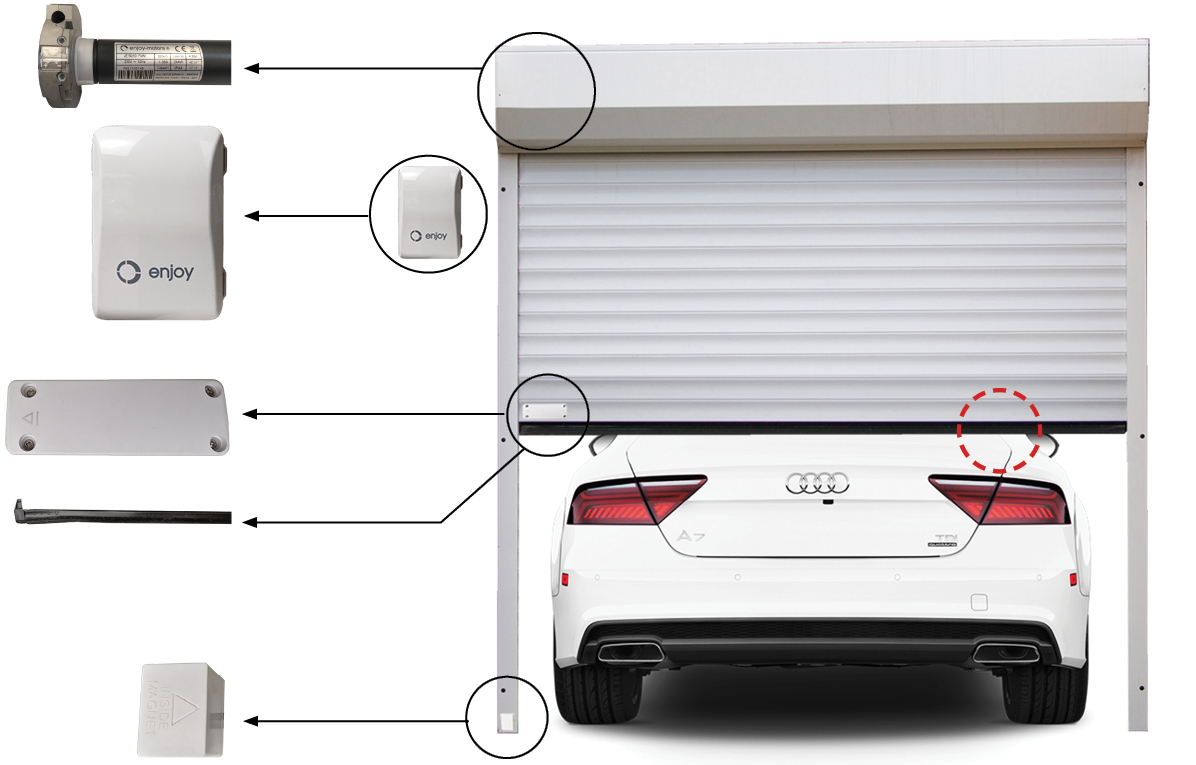

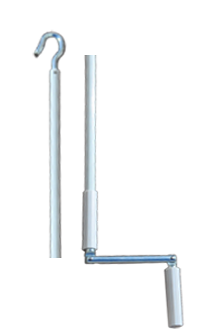

FMM system, motor with manual operation:

Motor JE60FMM has an internal cardan that allows the user to operate the motor through a crank. This operation gives the motor the security that, if necessary, either because it is a roller shutter from a terrace door, ..., we can close or open it even in the absence of electricity. At enjoy we have a series of accessories for the JE50FMM 1️⃣ motor such as the cardan or union fitting AS2029 2️⃣ and the crank AS1782 3️⃣

Traditional limits point setting:

Motor JE60FMM has the traditional limits setting. On the motor head there are 2 screws that are corresponding with the motor movement, represented by an arrow. It is very important to understand that said arrow does not indicate if the roller shutter is going uo or down, if you see the arrow or down, but rather indicates the rotation of the motor and therefore the movement that the shutter will perform.

in the example:

- the upper screw represented by the arrow ⬇ (green color) corresponds to the upper limit (because turning in that sense the blind is rolled up). For setting, we will turn the upper screw in the + direction if roller shutter has to rise more than it stops automatically or in the opposite way if it has to stop at a lower point

- the lower screw represented by the arrow ⬆ (red color) corresponds to the lower limit (because turning in that sense the blind is unrolling). For setting, we will turn the lower screw in the + direction if has to downwards more than its stops automatically or in the opposite way if it has to stop at a higher point

product available during the second half 2020

Option safety stop "safety edge":

- Transmitter unit. It receives the order by the rubber detector of the 2-wire terminal, and sends the stop order to the RECMAD03 receiver via radio under the freq. 433.92MHz

- Detector rubber for terminal

- Magnetic connector to deactivate the sensor when it reaches the lower point

As soon as the rubber is pressed by an object, the transmitter unit sends the order to stop the RECMAD03 receiver and it automatically stops the motor (or reverses the maneuver to release said object), avoiding further damage to both the roller shutter and the object that caused the alert:

Option safety stop "photocells":

As soon as the light beam is cut by an object, the RECMAD03 receiver automatically stops the motor (or reverses the maneuver to free the object), avoiding further damage to both the roller shutter and the object that caused the alert:

Wiring Option:

Technical data:

| JE60/80 16rpm | JE60/80 | JE60/100 | JE60/120 | ||

| NM | 80 | 80 | 100 | 120 | |

| RPM | 16 | 12 | 12 | 9 | |

| TURNS | 27 | 27 | 27 | 27 | |

| V~HZ | 230~50 | 230~50 | 230~50 | 230~50 | |

| A | 1,79 | 1,40 | 1,79 | 1,79 | |

| W | 410 | 315 | 410 | 410 | |

| MIN | 4 | 4 | 4 | 4 |

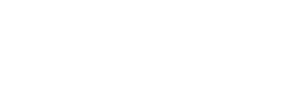

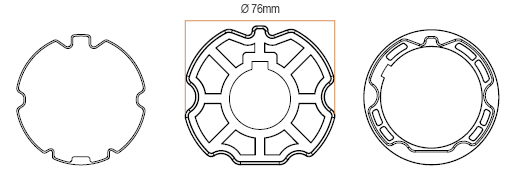

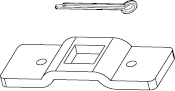

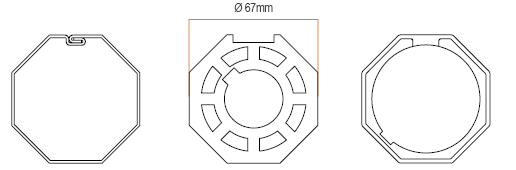

Main shaft adapters:

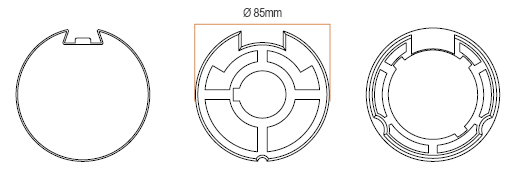

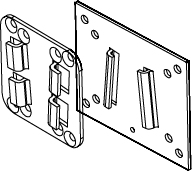

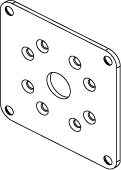

Main motor brackets:

SP1822 Bracket with plate in 100x100, thickness 5mm

SP1822ZF Bracket for ZF drawer with plate in 100x100, thickness 5mm

SP11649 Bracket for ZF 250/300 drawer with plate in 100x150, thickness 5mm

Compatible Products:

|

|

|

|

|

|

RECMAD03 |

ASSM062-2 |

ASSM062 |

AS0718 |

AS1782 |